Here are some steps.

1. Agricultural machinery application: There are a lot of different application in agricultural machinery such as :Rotary cutter,Rotary Mower, Power harrow, power plowing, spreader seeding, corn harvesting, post hole digger,Rotary tiller, rotary tedder, hay baler, etc.), the terrain (flat, hilly, rough), and the power requirements of gearboxes.

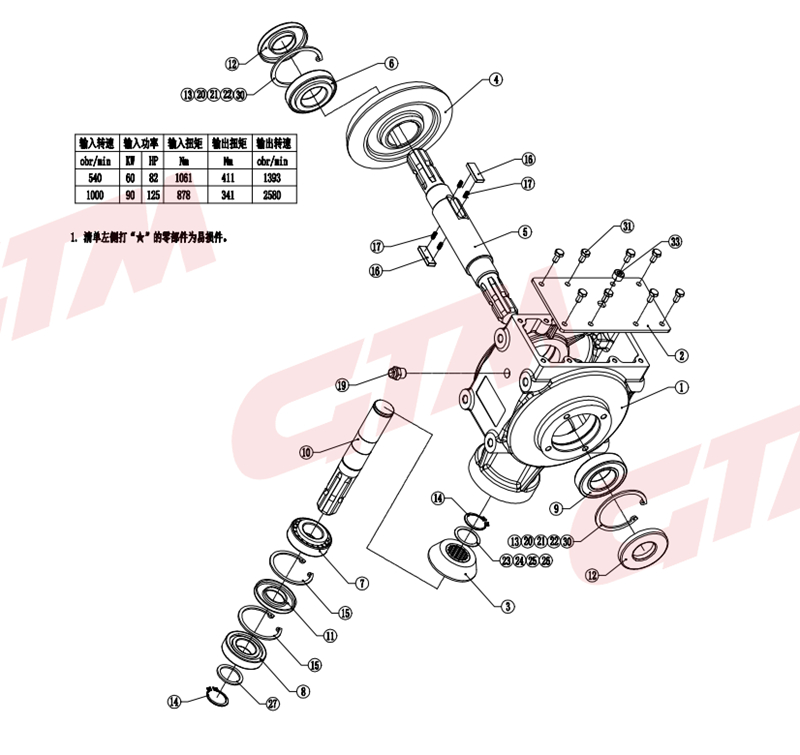

2. Power and Speed requirment(Ratio): For agricultural machinery, it requires the certain power to carry on the gearboxes.

Such as rotary mower gearbox(30-300hp),Rotary tiller gearbox(30-200hp) .

About the ratios can be customized as customer needs.

For input speed ,it will be around 540rpm or 1000rpm.

3. Gearbox Transmission efficiency: in the power transmission, the pto shaft will consume some power from tractor. Look for gearboxes with high power transmission efficiency to minimize energy losses during operation. Efficient gearboxes help maximize fuel economy and reduce operating costs. Good gear engagement,it will make gearbox with good life span ,and less noise.

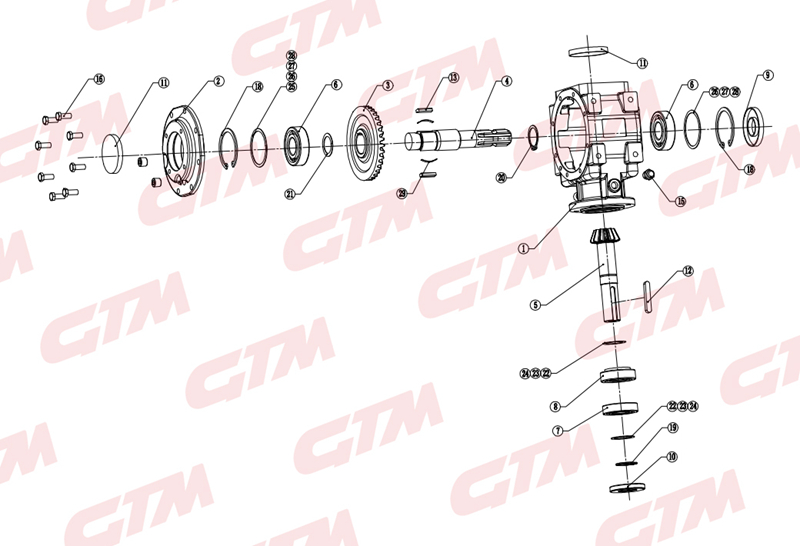

4. Consider Maintenance Requirements: Choose a gearbox that is easy to maintain and service. Accessible lubrication points, replaceable seals, bearings, gears, shafts, spcers, shims, and durable components can help minimize downtime and reduce maintenance costs